New isotropic 3D antennas for electromagnetic tracking systems. 3D9 and 3D22.

This new antenna range offers especially developed components, among others for the use in magnetic tracking systems. They are used in devices for different industries like gaming, logistics, maintenance and medicine. These antennas result from a combination of our expertise in the development and manufacturing of customized ferrites by injection molding as well as of electronic components.

Virtual information for the technology of the future

In a wide range of industrial fields, sensor systems are now increasingly being used to collect information on the position of an object in three-dimensional space. They use the data acquired to add virtual information to processes. Such approaches are used in the following fields:

Service and repairs

Where is the defective component in a system?

How can repair processes be performed optimally in the shortest time?

Even without special knowledge, service technicians can find their way around unfamiliar systems, localize errors, and perform repairs.

Medical technology

Virtual systems enable medical experts to perform risky operations without errors and to learn and carry them out in a very short period of time so that the patient is exposed to as little stress as possible.

Gaming

VR goggles are already expanding the sensory horizon in the gaming industry. In the near future, mixed reality technology will fuse real and virtual images into a single entity for the observer.

Technical solutions for 6DoF

There exist various methods for determining the position of an object in three-dimensional space. Two coordinates define the position in a plane. For the description of the object height, an additional piece of information is required. The result is 3D data. If this data is supplemented with information on the orientation of the object, the result is a set of 6 different information which describe the freedom of movement of an object in three-dimensional space (6 degrees of freedom; 6DoF).

Corresponding sensor systems can be built using various physical values. For this purpose, optical (camera-based), mechanical (with gyroscopes or gyrostats) or magnetic systems are used. Systems based on the first options have severe disadvantages:

Optical systems are generally based on complicated and time-consuming image processing methods which require fast processors. Furthermore, the data that can be collected is limited to the visible environment which can be captured by the camera system.

Mechanical systems have a complicated design and are subject to natural wear and tear, which limits their service life.

In magnetic systems, on the other hand, the advantages dominate. They do not require direct visual contact, which means they work in spite of surrounding obstacles and can be operated in a wear-free manner.

Magnetic tracking systems

Electromagnetic tracking systems generally require two components. A transmitting and a receiving antenna.

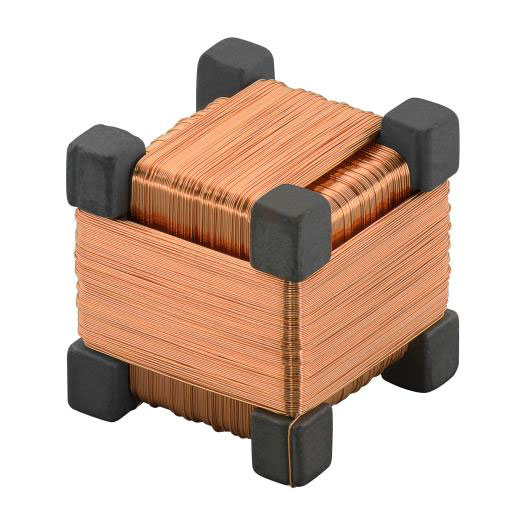

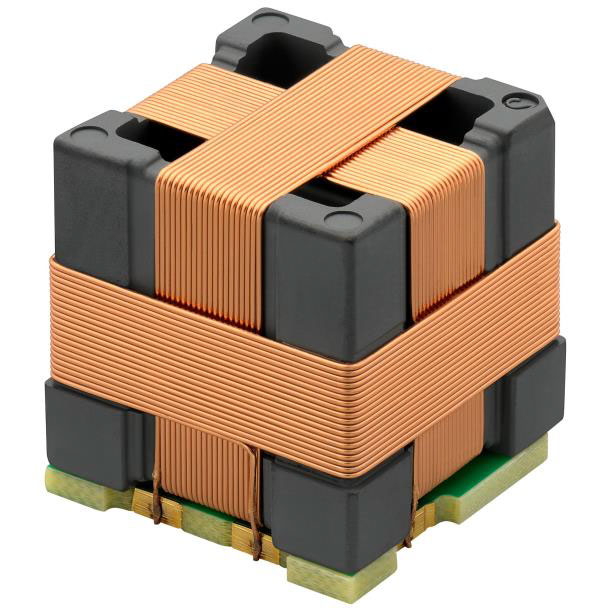

The magnetic waves generated in the transmitter induce voltages in the receiving antenna which are forwarded to the microprocessor-aided evaluation unit. The antennas each possess 3 orthogonally oriented coils for generating — i.e. collecting — information in all spatial axes (x-, y-, and z-axis). If these coils contain identical electrical and geometric properties, this corresponds to an isotropic antenna design. Such a unit shows advantages in the evaluation of signal information, as the transmitted outgoing and incoming signals can be related directly to each other. When these properties are bundled, the result assumes the shape of what is called a 3D cube antenna:

- Image 1: Antenna size 1

(9x9x9.9)mm

- Image 2: Antenna size 2

(22x22x22.9)mm

Design of 3D cube antennas — Innovations from NEOSID

We have optimized the 3D cube antenna with regard to all their electrical and mechanical properties as an electronic component. This allows their use and function to be realized as effectively as possible.

The antenna core

We utilize a special manufacturing process to form modern ferrite materials into any required three-dimensional shape. We use this to create a hollow ferrite core for our 3D cube antennas. Compared to a solid ferrite core, this significantly reduces the weight of the component — while retaining the efficiency of the antenna.

Our one-piece antenna cores offer the greatest degree of resistance against mechanical influences because we keep the number of components used low — thereby also doing our part for a sustainable environment.

Alternatively, we also realize isotropic antennas without a core — i.e. made of three air-core coils put together. This design variant is particularly important for applications in which magnetic materials are not to be used, e.g. in medical technology contexts.

Connection technology

Our proficiency in advanced manufacturing methods allows us to design 3D cube antennas such that they can be manufactured optimally in an automated production process. Furthermore, metallized areas on the ferrite core serve as contact surfaces for the individual windings as well as for contacting the entire component on the circuit board. With the latest modern manufacturing processes, we increase product quality and reduce production time. For the additional stabilization of the connection between the circuit board and antenna, we offer our optional patented HSF technology. Our components can be used directly with automated manufacturing machines in a reflow process.

X-, Y-, and Z-windings

The process-optimized ferrite core makes it possible to automatically wind the antenna. The wire thickness, number of windings, and winding position can be individually adapted to the requirements of the application. Utilizing proven contacting technology, we reliably attach the coil wire to the component.

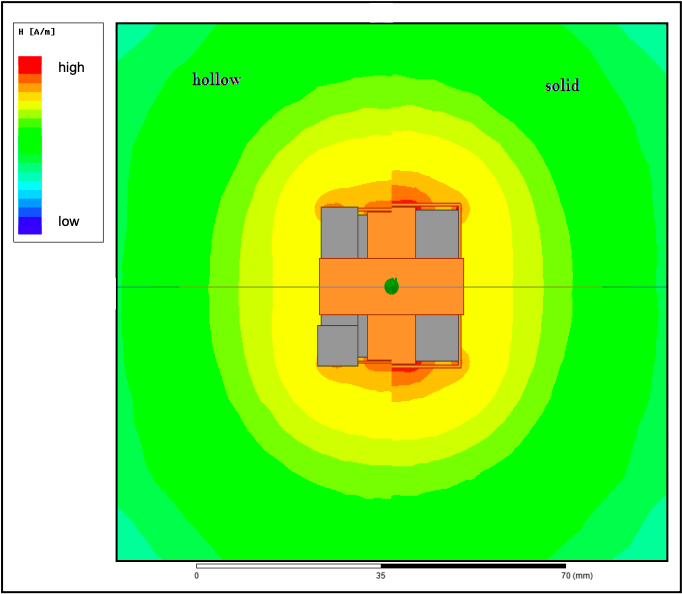

Simulations – Predicting if something will work

Technical requirements with regard to inductance, sensitivity, operating frequency, and additional parameters determine the design of 3D cube antennas. In comprehensive simulations, we provide evidence that the requirements have been adhered to. We can review every modification to the component — whether geometrical or electrical— in advance based on theoretical observations. In this manner, we adapt the antennas to the customer's specific environmental conditions and design a component that is optimally integrated into the customer's application.

- Image 3: Graphical representation of a simulation result

High vertical integration

The design, the creation of the production tools and the manufacturing of the ferrite cores for the antennas take place in Germany. For winding processes, we utilize modern, robot-controlled production facilities. Continuous quality control from the raw parts to the finished antenna ensure long-term quality and high rate of yield. We use advanced production methods along the entire manufacturing process.

3D9-RX antenna

Properties

- Isotropic 3D antenna

- Dimensions: (9.0 x 9.0 x 9.9)mm

- Customized shapes and designs upon request

- High sensitivity

- Temperature range: -20°C to +70°C

- Lead-free and RoHS compliant

- SMD

- Inductance range from 1 to 31mH

- Ferrite core or non-magnetic core

- Single-piece ferrite version: Ferrite core + metallization + wire

- Low weight, typ. 3 grams

- Hollow version with reduced weight available

Applications

- Keyless entry systems

- RFID transponders and systems

- Augmented reality, virtual reality, and mixed reality

- Electromagnetic positioning of objects

- Medical technology

- 6DoF applications

General description

The 3D9 antenna is a ferrite core antenna. The three coils on the antenna are oriented at right angles to each other. The cube shape of the antenna offers isotropic properties during transmission and reception in the x-, y-, and z-axes.

| L [mH] | ± % | fmess [kHz] | Q typ | RDC max. [Ω] | part number |

|---|---|---|---|---|---|

| 1 | 3.5 | 25 | 12 | 13 | 88807170 |

| 3 | 12 | 40 | 88807171 | ||

| 7 | 12 | 95 | 88807172 | ||

| 13 | 12 | 180 | 88807173 | ||

| 19 | 11 | 270 | 88807174 | ||

| 25 | 10 | 380 | 88807175 | ||

| 31 | 12 | 420 | 88807176 |

Customized L and RDC values on request. Please contact us for details.

3D22-TX antenna

Properties

- Isotropic 3D antenna

- Dimensions: (22.0 x 22.0 x 22.9)mm

- Customized shapes and designs upon request

- Lead-free and RoHS-compliant

- SMD

- Ferrite core or non-magnetic core

- Hollow ferrite core (up to 50% weight reduction compared to solid ferrite shape)

- Low weight, typ. 25 grams

Applications

- Keyless access systems

- RFID transponders and systems

- Augmented reality, virtual reality, and mixed reality

- Electromagnetic positioning of objects

- Medical technology

- 6DoF applications

General description

The 3D22 antenna is a ferrite core antenna. The three coils on the antenna are oriented at right angles to each other. The cube shape of the antenna offers isotropic properties during transmission and reception in the x-, y-, and z-axes.

| L [mH] | ± % | fmess [kHz] | Q typ | RDC max. [Ω] | part number |

|---|---|---|---|---|---|

| 30 | 7 | 25 | 22 | 0.210 | 88807180 |

| 60 | 15 | 0.590 | 88807181 | ||

| 90 | 13 | 1 | 88807182 | ||

| 120 | 11 | 1.6 | 88807183 | ||

| 150 | 9 | 2.2 | 88807184 | ||

| 180 | 8 | 3.1 | 88807185 | ||

| 200 | 7 | 3.7 | 88807186 |

Customized L and RDC values on request. Please contact us for details.

Tell us your requirements – we will develop the fitting solution for you!

Have we aroused your interest? Then get in touch with us.

Download

PDF „3D cube antennas for electromagnetic 6DoF tracking systems“