Product overview and possible applications

Summary

Planar transformers enable compact, efficient and thermally optimised solutions for modern power supplies. Their layered structure offers advantages such as low stray inductance, high power density and excellent EMC properties. This white paper shows why planar technology plays a key role in applications with limited installation space and high efficiency requirements – from industry and automotive to medical technology.

Introduction

At a time when power electronics must become increasingly compact, efficient and thermally robust, conventional transformer solutions are increasingly reaching their limits. Planar transformers offer a sustainable alternative here: they combine a space-saving design with high power density and excellent thermal behaviour.

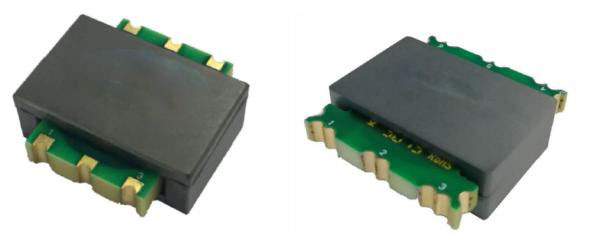

- Figure 1: Classic transformer

- Figure 2: Planar transformer

This white paper introduces our new product group of planar transformers, which have been specially developed for use in modern power electronic systems – from industrial applications and charging infrastructures to demanding automotive environments.

As a long-standing supplier of customised transformer solutions, we combine technological innovation with proven development and manufacturing expertise. The aim of this document is to demonstrate the advantages and possible applications of planar transformers in a practical manner and to introduce our product solutions.

Product group overview

This new product group comprises planar transformers in the power class from 1 Watt to 10 Kilowatts output power. Depending on the application, operating voltages up to 1,000V are covered. With a suitable design and appropriate materials, insulation voltages of up to 4,500V can be achieved. The flexible design of planar transformers allows the integration of multiple windings and functional units to reduce wiring effort and assembly space. Operating frequencies range from 50Hz to 1 MHz. In addition to standard ferrite cores, we also use customer-specific cores, which are developed by us according to specifications and manufactured in-house.

- Figure 3: Planar transformers with up to 20-layer multilayer printed circuit boards

- Figure 4: Planar transformer with windings made of printed circuit boards and wire coils

Below is an overview of the advantages that planar transformers offer compared to conventional transformers:

| Feature | Classic Transformer | Planar Transformer |

|---|---|---|

| Height | 100 % | -30 % to -50 % |

| Heat Dissipation | via the Surface internal Hotspots | homogeneous distribution hardly any hotspots |

| Stray Inductance | 1 % to 5 % | 0.1 % to 0.5 % |

| Reproducibility | process-dependent | excellent |

| Frequency Range | 20 kHz to 200 kHz | 100 kHz to 1MHz |

Our product solutions

We manufacture our planar transformers in a wide variety of designs and sizes. We use different winding configurations depending on the number of turns and power class.

A typical feature of planar transformers is that the windings are realised on a printed circuit board. Two-layer and multilayer printed circuit boards are used for this purpose (see Figure 3). Alternatively, the individual windings can also be made of foil or classic winding wire.

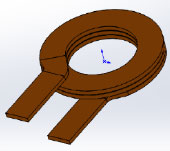

- Figure 5: Copper foil winding

- Figure 6: Copper flat wire winding

As a manufacturer of soft magnetic ferrites, we supply the core material for high-performance planar transformers. Our ferrite cores can be customised for specific applications – for maximum efficiency, optimised thermal properties and maximum design freedom. This enables us to provide tailor-made solutions for transformers that are precisely matched to the requirements of modern electronic systems.

We manufacture our ferrite cores from a total of 17 specially developed materials based on nickel-zinc (NiZn), manganese-zinc (MnZn) or composite materials. These material systems have been specifically developed for different areas of application in order to enable optimum magnetic properties for inductive components – across different power classes, temperature ranges and operating frequencies.

In addition to the classic dry pressing process, we also use a special injection moulding process. This allows the production of complex geometries and offers maximum flexibility in shaping – ideal for making optimum use of the available installation space in demanding applications.

Typical applications / use cases

Planar transformers are primarily used in applications where compact designs, high power density, good thermal properties and low stray inductance are required. They are preferred in power- and space-critical applications.

Here is an overview of typical areas of application :

Industry

Planar transformers offer high reliability and EMC-compliant design in confined spaces. This makes them particularly suitable for switching power supplies in machine controls, DC/DC converters for automation systems, compact DIN rail power supplies or power supplies for high-frequency welding systems.

Automotive

Space-saving solutions with high thermal load capacity are required here. Possible areas of application for planar transformers include on-board chargers (OBC), DC/DC converters in electric and hybrid vehicles, power electronics for driver assistance systems (ADAS) or HV/HV isolation in traction systems. With operating temperatures between -40 and +155°C, our planar transformers are also suitable for installation in the engine compartment. Many of our transformers meet the requirements of AEC-Q200.

Medical technology

With their low height, good insulation properties and reliable heat dissipation, planar transformers are particularly suitable for use in medical technology. Applications here include power supplies in imaging devices (e.g. MRI, CT), examination devices with galvanic isolation and laboratory equipment with special safety requirements.

Renewable energies

High efficiency over a wide operating frequency range and good EMC properties play a particularly important role here. Planar transformers are used in DC/DC converters in photovoltaic inverters, battery management systems (BMS) and power supplies in wind turbines.

Telecommunications / Data centres / Servers

With their flat designs, high packing density and suitability for parallel power architectures, planar transformers are ideal for Power over Ethernet (PoE), power supplies for servers, switches and routers, and as DC/DC converters in uninterruptible power supplies (UPS).

Aerospace / Railway technology / Defence and security

Planar transformers offer decisive advantages in these applications, particularly in terms of reliability, robustness, space savings and thermal efficiency. Due to the high demands in these applications (e.g. shock, vibration, extreme temperatures, electromagnetic interference), classic transformer solutions are often too bulky or insufficiently stable – this is where planar transformers come into their own. They are used in power supplies with extreme requirements in terms of weight, volume and reliability, as well as for galvanically isolated signal and power transmission.

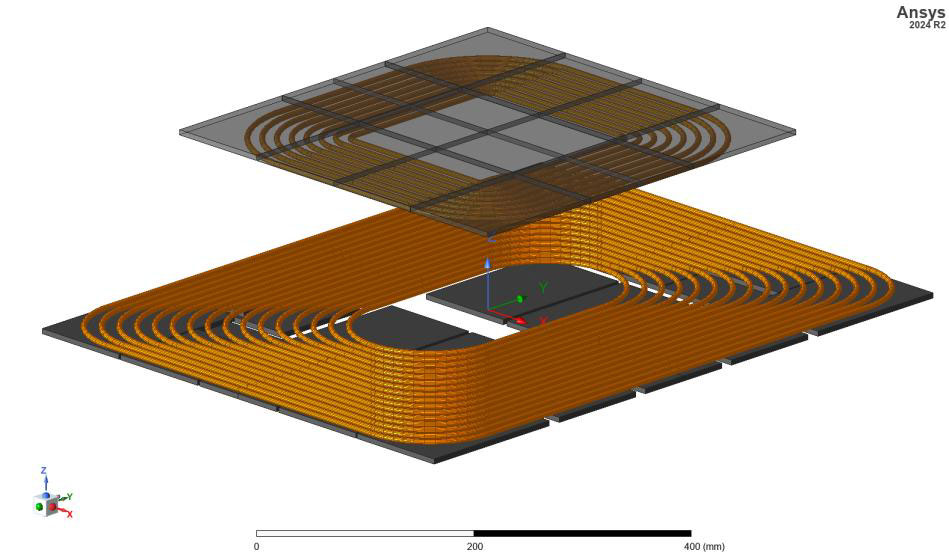

Our expertise & development competence

The development of planar transformers requires comprehensive technical expertise from various specialist areas. This includes, above all, electromagnetic design and simulation in order to precisely optimise winding design, inductance values and stray losses. Equally important is thermal design, which ensures efficient heat dissipation concepts and the selection of suitable materials.

- Figure 7: Electromagnetic simulation with ANSYS Maxwell

In-depth knowledge of soft magnetic materials and insulation materials forms the basis for high-performance, reliable transformers. Neosid has over 90 years of experience in this field and offers a wide range of suitable materials. This is complemented by knowledge of printed circuit board technology, as planar transformers are often designed as PCB-based components and require a special high-frequency and high-current layout.

CAD-supported component design results in stable housings and mounting variants that function reliably even under harsh conditions. Manufacturing expertise and quality assurance are crucial for controlling series processes and ensuring high product quality.

In addition, knowledge of relevant standards, safety requirements and certifications is important, as is a deep understanding of system integration and application requirements. Interdisciplinary collaboration and clear communication with customers, manufacturing and development teams round off our competence profile.

Conclusion

The use of planar transformers offers customers a number of key advantages – in technical operation as well as in product design and manufacturing. Thanks to their compact and flat design, planar transformers enable space-saving integration into modern devices while offering high power density. The flat design supports particularly efficient heat dissipation, which means that thermal stress can be reliably controlled even in performance-critical applications.

Another technical advantage is the low stray inductance, which leads to higher efficiency and improved EMC behaviour. Since the windings are manufactured in the form of printed circuit board structures, the components are highly reproducible – an important factor for series production and applications in the high-frequency range.

As a customer, you benefit from Neosid's high design flexibility in development and design: we enable tailor-made solutions for specific requirements.

Tell us your requirements - we will develop the right solution for you!

Have we aroused your interest? Then contact us about the latest generation of planar transformers.

Download

PDF „Efficient energy transfer with planar transformers – setting new standards for power electronics“