Topics

- Common exploited properties of Ferrites

- Forming fields

- Shaping ferrites

- Contacting coils

- Permeability μ changes with

- frequency | temperature

- air gap | excitation level

- DC bias/magnetic fields | mechanical forces

Properties and applications of Ferrites 1

- “collecting” and shaping of magnetic fields

➤ sensors, antennas, transponders - Increasing “inertia” of electric current

➤ chokes, noise suppression, filters, delay lines - Increase magnetic coupling of conductors

➤ transformers, converters, storage chokes,

impedance matching

Antennas and Sensors

Metal detection and recognition

- source: IFM

Inductive proximity switch:

Directing and focussing magnetic field

- source: http://eddycation.de/

Non destructive Material testing:

- Material sorting (e.g. Coin recognition)

- Material thickness (e.g. Coin recognition)

- Crack detection and depth determination

- Imaging of material faults

Dry pressing of ferrites

Cross-section through a sintered pot core

pressed part before sintering

powder column in the mould before pressing

uneven densification

➤ strains and cracks,

particularly at the lines

where portions of

different thicknesses meet

Crack formation in pressed ferrites

Density differences during powder pressing

➤ differing densification in thinner and thicker

areas of the part can cause

crack formation at the intersections

Examples for injection molded parts

Isotropic 3D-cube antenna 9x9x9mm

- monolytic, hollow ferrite

- high Q-factor, high sensitivity

- reduction in material and weight

smallest customer specific designs

- wall thickness ≥ 0,22mm,

- volume ≥ 1mm3

- tolerances down to +-1%

SMD transponder coils

- high Q-factor, high sensitivity

- high reliabilty in vibration und drop tests

Ferrite production at NEOSID

| mixing oxides | main components Fe Mn Ni Zn |

|---|---|

| pre sintering | homogenization and formation of the ferrite structure |

| milling | creating a very fine powder |

| compounding | mixing ferrite powder and binder |

| injection moulding | 1 to 28 cavities |

| barrel finishing | rounding edges, removing flash |

| sintering | in air or under controlled oxygen concentration |

| annealing | establishing an optimum domain structure |

| grinding | tight tolerance, flat surface, round, thread grinding, CNC milling of prototypes |

| coating | e.g. parylene, self-locking screw cores, metallization |

| Inspection | electrical, geometrical |

Contacting Technologies

Wire wound terminal

Metal pin terminal

Metallized core terminal

Common competitors Metallisations

Dipping

Dipping in silverpaste, burning in and plating

➤ low quality factor caused by eddy currents in end faces

➤ Nickel-Zink-Ferrite only

single layer PVD

selective deposition of e.g. silver

➤ poor adhesion

➤ dissolves during soldering, does not withstand thermocompression

Metallisation from NEOSID

3-layer PVD

selective deposition of 3 layers where whished for, no burning in

➤ reduction of eddy currents

➤ works on Manganese- and Nickel-Zink-Ferrite

➤ good adhesion

➤ withstands soldering and thermocompression

automated 100 % optical inspection

Soft magnetic Ferrites

NiZn-Ferrites

- μi from 10 to 2.000

- high Q between 0 and 100 MHz

- large electrical resistance

- higher Tc

- sintering in air

MnZn-Ferrites

- μi from 700 to 20.000

- high Q between 0 and 1 MHz

- small electrical resistance

- lower Tc

- sintering under controlled atmosphere only

Influence of Frequency

μ‘ = permeability

μ‘‘ = losses

Q = μ‘/μ‘‘

For lower losses (higher Q) at higher frequencies chose lower μ material

Influence of Temperature

Medium and small μi

- Very small temperature drift

High μ

- Almost linear temperature drift

(can be compensated)

Very high μ materials

Very unstable μ

➤ troublesome compensation

Sources: TDK-Catalogue

Only for very low

frequency applications

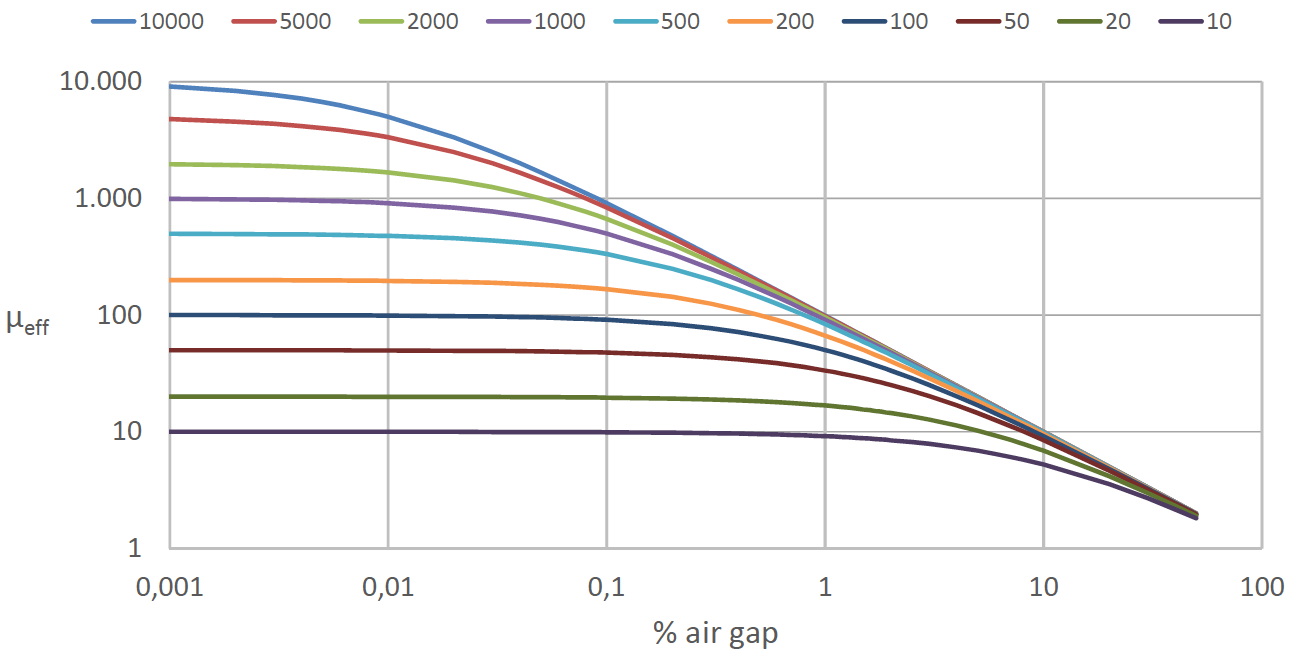

Influence of air gap

Air gap: Fraction of magnetic path not

running in ferrite material

- μeff vs. % air gap for varying μi

Sensing Coils are mainly open magnetic circuits

with a large air gaps (≈ 50% for a pot core).

- source: IFM

The larger the air gap, the less difference in μeff

remains between high and medium μ materials.

Influence of excitation level

Initial permeability μi is

μ measured at low excitation

levels (B < 0,5 mT)

μa changes at high excitation

levels

With open magnetic circuits

μeff << μa

B = μeff*μo*H is rather small

and sensors usually work in

stable μ regime

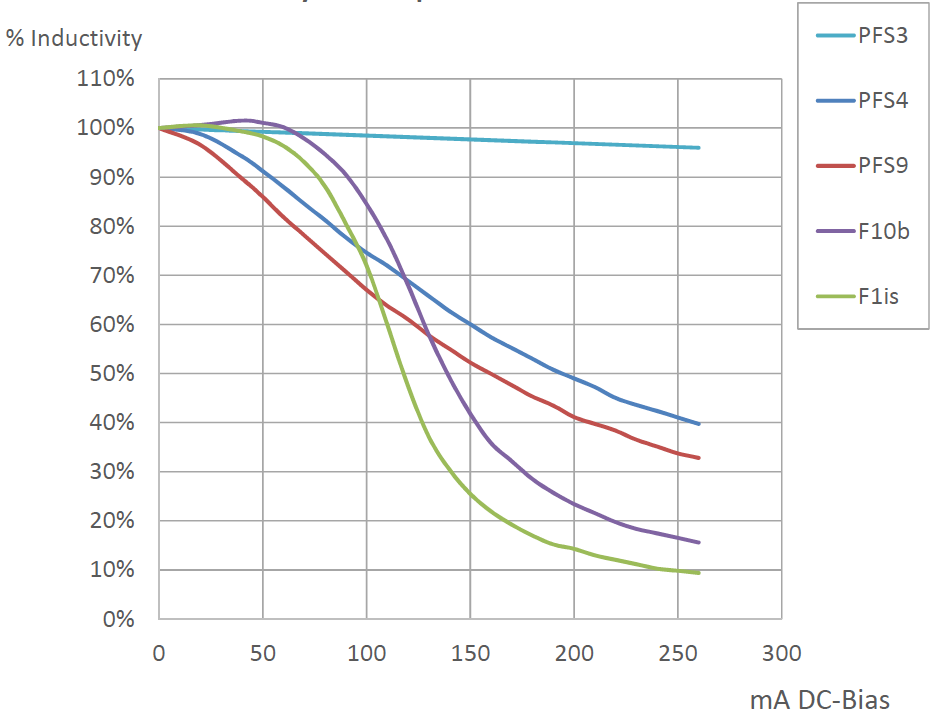

Influence of DC-Bias and external Fields

- Inductivity of transponder-Coil vs. DC-Current

Permeability decreases with

application of

- DC-bias

- external magnetic fields

ferrites stay stable up to a certain

level and than drop quite fast

Higher μ ferrites suffer earlier

Composites PFS4 and PFS9

drop earlier but slower

Composite Material PFS3 is

extremely stable

up to > 1000 mT

Impact of strong magnetic fields and excessive mechanical force

3 ferrite material classes

NiZn-ferrites F2a to F100b

- Some impact, extremely slow recovery

- complete recovery can be reached only through thermal annealing

- a-Types (like F2a) are less sensitive

MnZn-ferrites F02 and F08

- impact, but fast recovery

NiZn-ferrites F1ib, F1is, F5is and Composite Materials

- hardly any impact

Composite materials

- Hardly any impact

- distributed air gap ➤ lower permeability

- Saturation flux density > 1000 mT for PFS3

- Tighter mechanical tolerances

- Easy to machine

What do you need ?

High Q value at your frequency

- wide range of ferrite materials F02 to F100

- number in name gives maximum frequency in MHz

for which high Q is still achieved (02 is 0.2 MHz)

Excelent temperature stability

- materials F2 to F100 are your choice

High temperature applications

- Materials with Curie Temperature ranging

from 150 to 600 °C are available

Highest excitation levels

Large DC-Bias or strong external magnetic fields

- PFS3 will do your job

Temporary Magnetic or mechanical stress

- F1ib does not remember the torture

Smallest sizes, Customized shapes

Complicated geometries, Design for automation

- Ceramic Injection Moulding of ferrites

turns your vision into products

Contacting Pads, Shielding

Thermal compression of wire ends

- Selective metallization of ferrites serves your needs

Medical applications

- Parylene coating gives you coverage

You do not like cables and plugs

- Wireless data and power transfer gets rid of cables

Wireless power and data transfer

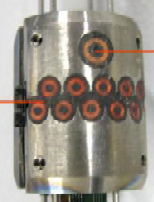

Rotating scanner system

Energy transfer from primary to secondary side.

Bi-directional data transfer

Properties and applications of Ferrites 2

Less common thought of properties of soft magnetic ferrites:

- Magnetostriction

➤ Ultrasonic actuators and sensors, “invisible speakers” - Lossy interaction with fields from MHz to some GHz

➤ Inductive Heating, selective microwave heating - Colour and magnetics

➤ Copier powder - DC-Magnetization

➤ Switchable mechanical forces

Tell us your requirements – we will develop the fitting solution for you!

Have we aroused your interest? Then get in touch with us.

Download

PDF „Ferrites for sensor applicatons – design and properties“