NEOSID develops and produces a broad portfolio of electronic components that meet the highest requirements in industry, defence and heavy-duty applications. Our products are manufactured at our main site in Germany in close co-operation with our customers. The Halver site is home to ferrite production, a manufacturing unit for small series and prototypes as well as fully automated production lines. Additional production facilities in the EU and Asia enable both manual and highly automated series production.

With over 90 years of experience and a comprehensive product portfolio, we set standards in the development and production of electronic components.

Below we present our most important product areas:

Ferrites

Ferrites are NEOSID's original product. We have been developing and producing our soft magnetic ferrites 100% in Germany for over 90 years. We select the optimal material for each application from over 15 specific materials. We use both dry pressing and injection molding processes to create customer-specific geometries that meet the highest electromagnetic and mechanical requirements.

- Optional metallisation: For integration on printed circuit boards or on connection cables.

- Typical applications: Soft magnetic cores for inductive components and shielding against electromagnetic waves.

- Figure 1 – Injection molded ferrite core with metallised surfaces

High-frequency coils without winding core

Our air coils are available in various designs and sizes, with wire thicknesses from 0.2 mm to 3.0 mm. We use different types of wire, including enamelled copper wire, selfbonding enamelled wire and silver-coated wire.

- Designs: THT und SMD components

- Special features: Customised pick-and-place pads enable automatic placement of the air coils and can be removed after placement to enable inductance or frequency adjustments.

- Areas of application: Electronic circuits in MRI devices and high-frequency applications above 200 MHz.

Coilformers as well as production and testing equipment are developed in our internal process department. Our own toolmaking department ensures precise realisation.

- Figure 2 - Air coils made of enamelled copper wire with pick-and-place area

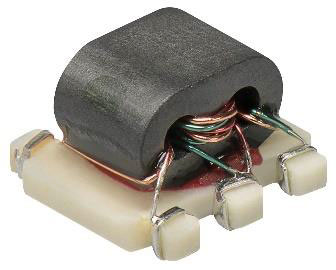

Transformers

Our customised transformers are created using standardised components such as bobbins, ferrites and winding wires.

- R&D: Product design, development and testing take place at our headquater in Germany.

- Production quantities: From small quantities to large series, manufactured using state-of-the-art production facilities.

- Customisation options: Expertise in materials enables the development of special transformers according to individual requirements.

- Figure 3 – Customised transformers made from standard components

Transponder antennas

NEOSID produces a wide range of rod core antennas in THT and SMD designs as well as customised versions. The ferrite cores used come from our own production facilities, which enables quick customisation.

- Frequenzbereiche:

- LF: 125/134.2 kHz

- HF/NFC: 13.56 MHz

- UHF: 434/868 MHz

- Special features: High inductance combined with compact design and high Q value and sensitivity.

- Applications: Especially for RFID applications on the reader and transponder side.

- Figure 4 – SMD rod core antenna

- Figure 5 – SMD transponder coil Ms 5420

RFID Transponder

- Figure 6 – HF RFID transponder as Inlay, Plug and Flag

Our passive RFID transponders fulfil the highest technical requirements, including a maximum ambient temperature of 275 °C.

- Construction: Patent-protected plug housing is inserted into a drill hole so that it is nearly invisible and firmly attached to the object.

- Features: Miniaturised design thanks to optimally matched components. The soft magnetic ferrite body works as the magnetic core of the transmitting/receiving antenna and as a mechanical carrier for the RFID IC.

- Quality assurance: Automated production machines guarantee the highest product quality.

- Applications: For reliable digital identification of objects under harsh environmental conditions, for example with the NeoTAG® plug transponders.

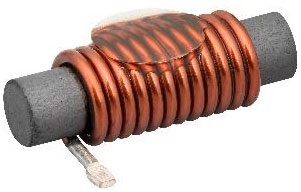

High frequency transformers

NEOSID is an expert in high-frequency inductive components. Our HF transformers offer excellent transmission qualities up to 2.4 GHz.

- Applications: Directional couplers and RF transformers with electrical isolation, e.g. for digital video transmission.

- Figure 7 – SMD directional coupler SM-T4 for signal transmission up to 2.4 GHz

Adjustable filter coils

Our filter coils can be used in the frequency range from 0.1 to 200 MHz.

- Designs and pitches:

- Filter 5: pitch 1.8 mm.

- Filter 7: pitch 2.25 mm.

- Filter 10: pitch 2.5 mm.

- Recommended frequency ranges:

- Up to 15 MHz: Filter 7.1.

- Beyond 15MHz: Filter 5.1, 7.1 S, 7.1 K, 7.1 E und 10.1.

- Figure 8 – Filter 10.1

Customised component designs are our speciality! Thanks to our special injection molding process for ferrite cores we can produce customised parts for your application - individually designed according to the defined task and exactly in the specified installation space.

Tell us your requirements - we will develop the right solution for you!

Have we aroused your interest? Then contact us about the latest generation of electronic components for mission critical applications.

Download

PDF „Electronic components for mission critical applications“